Hey everyone,

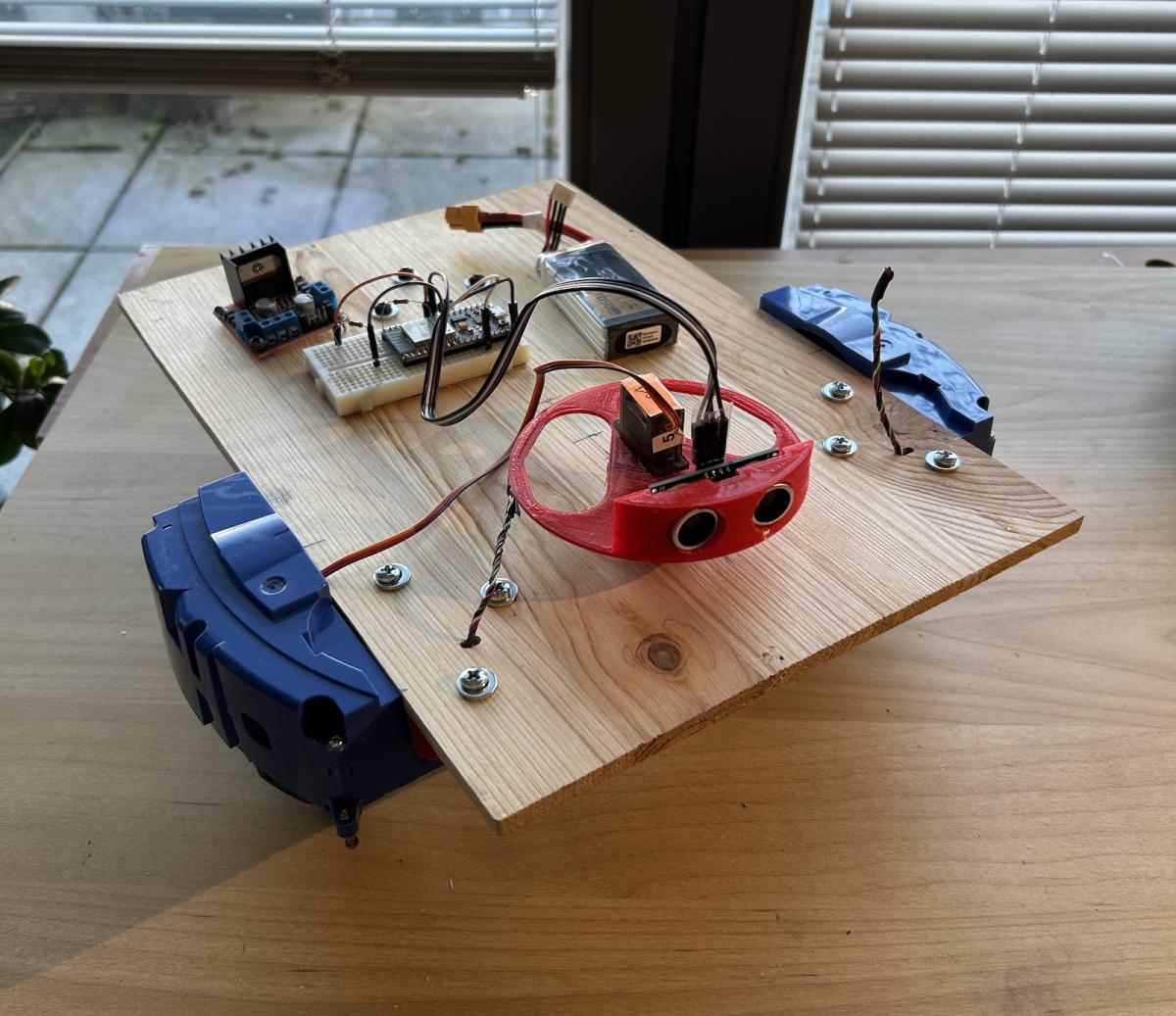

I wanted to share the start of my new robotics project, Minone, which is my MVP (Minimum Viable Prototype) for an exploration-focused robot. My goal with this build is to learn and refine SLAM (Simultaneous Localization and Mapping) using simple sensors, focusing on the fundamentals before scaling up.

Instead of jumping straight into complex sensor suites like LiDAR, I’m starting with basic ultrasonic and IR sensors to tackle obstacle detection and mapping. The idea is to deeply understand SLAM implementation—both from a theoretical and practical perspective—before adding more sophisticated hardware.

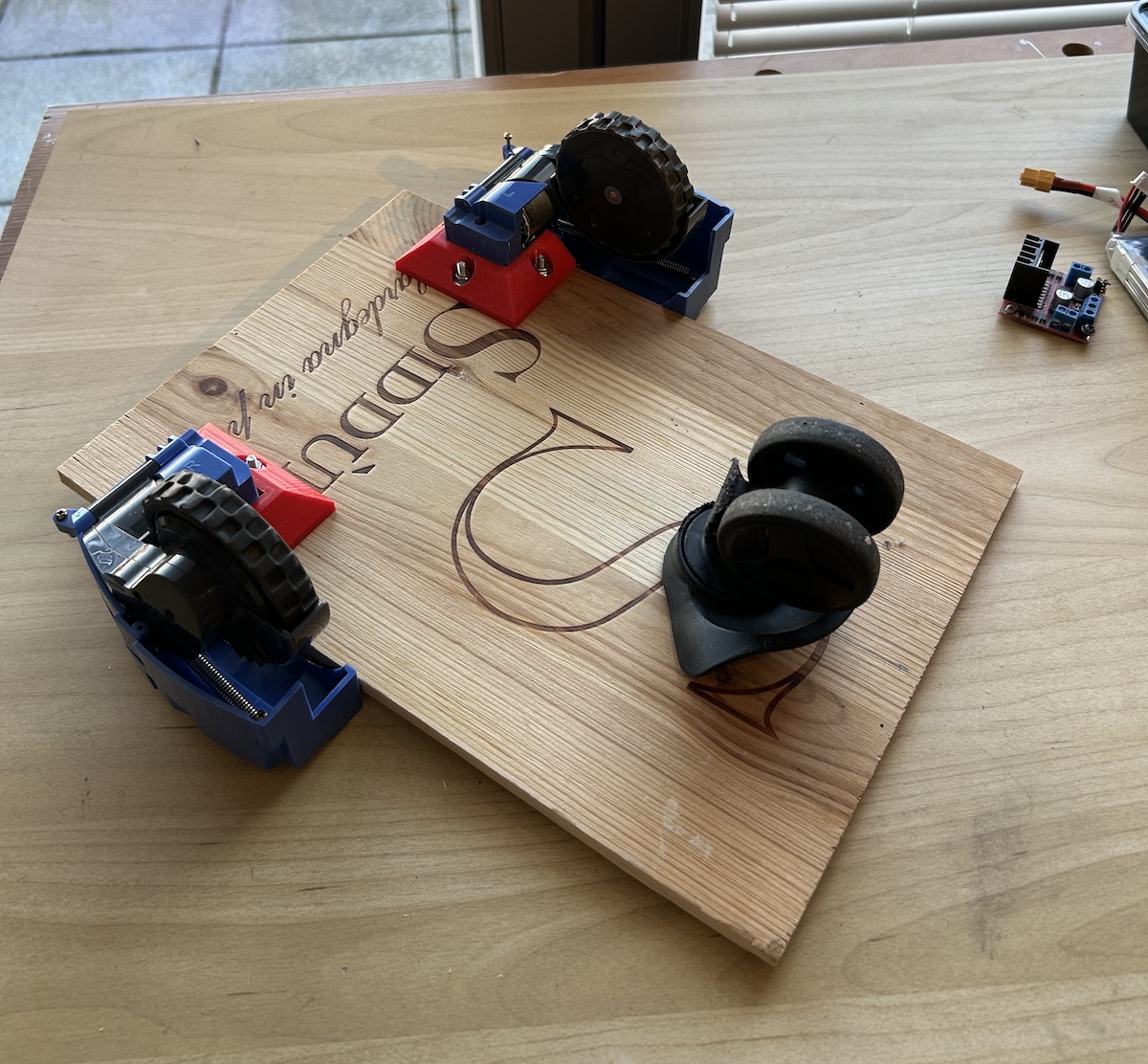

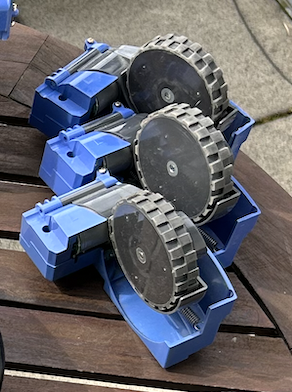

Right now, I’m putting the basics of the physical robot together using components I already have lying around. The chassis? A wine box top. The drive system? Two old Roomba motors bolted to it, with a recycled caster wheel from a trashed piece of luggage. It’s a real scrap yard robot, but that’s part of the fun—keeping it simple, functional, and iterative.

For the microcontroller, I’m going with an ESP-32S, and motor control will be handled by an L298N H-Bridge, which should handle the voltage needs of the Roomba motors just fine.

For initial sensing, I’m starting with a single Ultrasonic HC-SR04. Yes, it’s extremely underpowered for SLAM, and that’s completely intentional. My goal isn’t to throw advanced hardware at the problem but to push minimal sensors as far as possible. That way, I can deeply understand how to extract useful mapping data before moving on to more capable sensors.

I’d love to hear any feedback on my approach so far—especially if you have thoughts on driving a two-wheeled robot with a trailing caster wheel. I’m already second-guessing the design due to stability issues and occasional tipping forward, so if you’ve dealt with this before, let me know what worked for you. Also, this is my first project using an ESP-32S, so any tips on working with it—particularly for motor control and encoder integration—would be much appreciated!

Minone:

Underside of Minone:

Roomba wheel (DC motor control, and Encoder)

Mon contenu

Mon contenu Non spécifié

Non spécifié

Posté par

Posté par